Menu

Software Solutions

HOME > SOLUTIONS > SOFTWARE SOLUTIONS

SOFTWARE SOLUTIONS

Integra Connect

Connection software to integrate different equipment.

Integration with equipment and information systems

- Centralises multi-brand equipment.

- Supports multiple coding technologies.

- Reduces movements within the production plant.

- Reduces errors/mistakes and hence reducing downtime.

- Control of equipment and production at any time and from anywhere

Integration with the information system

- Item Master and planned manufacturing orders.

- Log of coded products and coding errors register.

- Linking tools and others from the leading ERPs based on text file (TXT / CSV)

- Integration with label design programs.

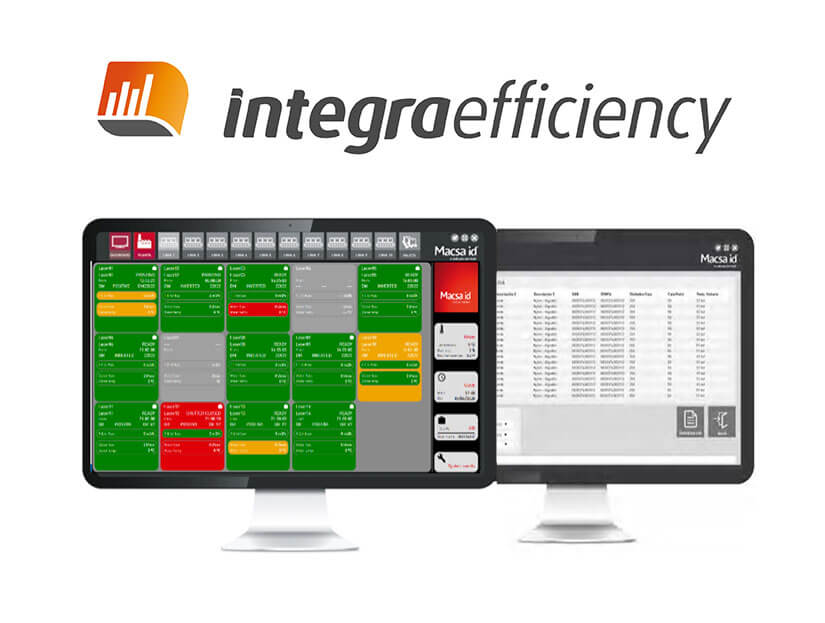

Integra Efficiency

Monitoring system for efficiency management and line optimization.

Automated collection and production data analysis.

- Complete, relevant, and reliable information in real time.

- Eliminates the possibility of error or variation arising due to manual entry.

- Records event details that could be forgotten.

- Rapid identification of opportunities for improvement.

- Identification of production trends.

- Reports available from anywhere via mobile and electronic devices.

Display of all parameters.

- Motivation to keep to production goals.

- Rapid reaction to possible setbacks.

- Fostering a culture of achievement and continuous improvement.

Integra Vision

Solution for verification and control of coding and production.

Integra Vision by Bradma Macsa ID is a solution that enables you to inspect and identify all of the products on the production line. This software tracks the product, from the manufacturing phase to the customer, and also ensures accurate labelling by checking text and codes.

Vision systems

- Fixed industrial ID scanners

- Handheld industrial ID scanners

- Code verifier

- Vision cameras

Integra Track & Trace

Traceability solution for production processes.

Integra Track&Trace by Bradma Macsa ID can record the origin of raw materials and the destination of finished products. It also complies with traceability regulations since it records all the production process.

This software consists of three solutions:

- Integra traceability: production control, quality and traceability control in the plant and in the office.

- Integra plant traceability: control and monitor the supply, production and shipments.

- Integra traceability desktop: all the data related to traceability and quality control.

Recommended for food, horticultural, beverage, pharmaceutics, and meat companies

Integra Optima

Application for the centralized management of the coding, marking and identification process.

Deplete the number of interventions.

To avoid the high probability of an error due to human intervention, Macsa ID provides Optima software, which centralises the entire coding and marking process in a single point, reducing the number of interventions and, therefore, the risk of errors.

More efficient coding of your products.

- Reducing the number of errors in coding

- Integration with most ERPs

- Controls traceability in the coding process

- Information in real time on the production lines

The PLUS version of Bradma Macsa’s ID Optima software is available.

Integra Serialization

Software for the individualized traceability of the supply chain.

Integra Serialisation by Bradma Macsa ID gives each product a unique serial number, allowing it to be validated at one or more points of the supply chain, thus complying with the FMD (Directive 2011/62/EU3) & other regulations.

Features:

- High-speed serialisation

- Print-verification- rejection cycle: only properly marked products are recorded, with the specified content and quality parameters.

- Serial numbers obtained: using generation schemes and file import

- Bottom-up/Top- down serialization modes

- Serialized production export

Integranet 4.0

Software module for remote management of data and equipment.

Bradma Macsa ID integraNET is a new approach that supports the structure of new technologies and tools Macsa 4.0. IntegraNET is a platform that incorporates solutions for monitoring, predictive maintenance, remote technical assistance, and production support.

There are two fundamental mainstays in this transformation of the services:

The equipment is intelligently designed so that it is capable of providing us with status information, to make autonomous basic decisions, and it is capable of being interconnected with other equipment and information systems. In addition to facilitating the exchange of components, it helps minimize down-time.

The collection and distribution of data must occur in both ways, simultaneous and global, all systems for distributing the information and operation of the machines are in real time. Cloud architecture is a key aspect in of the intelligent distribution of information collected from various sources, including processing and decision-making support.

Due to the high degree of interconnection and intelligence we can provide far superior efficiency levels than the current services.